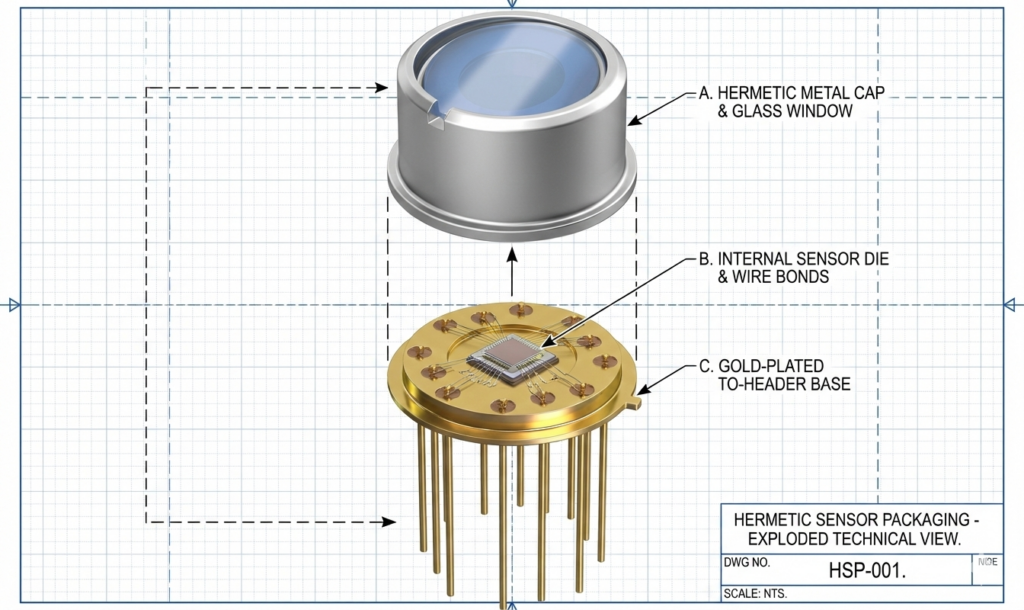

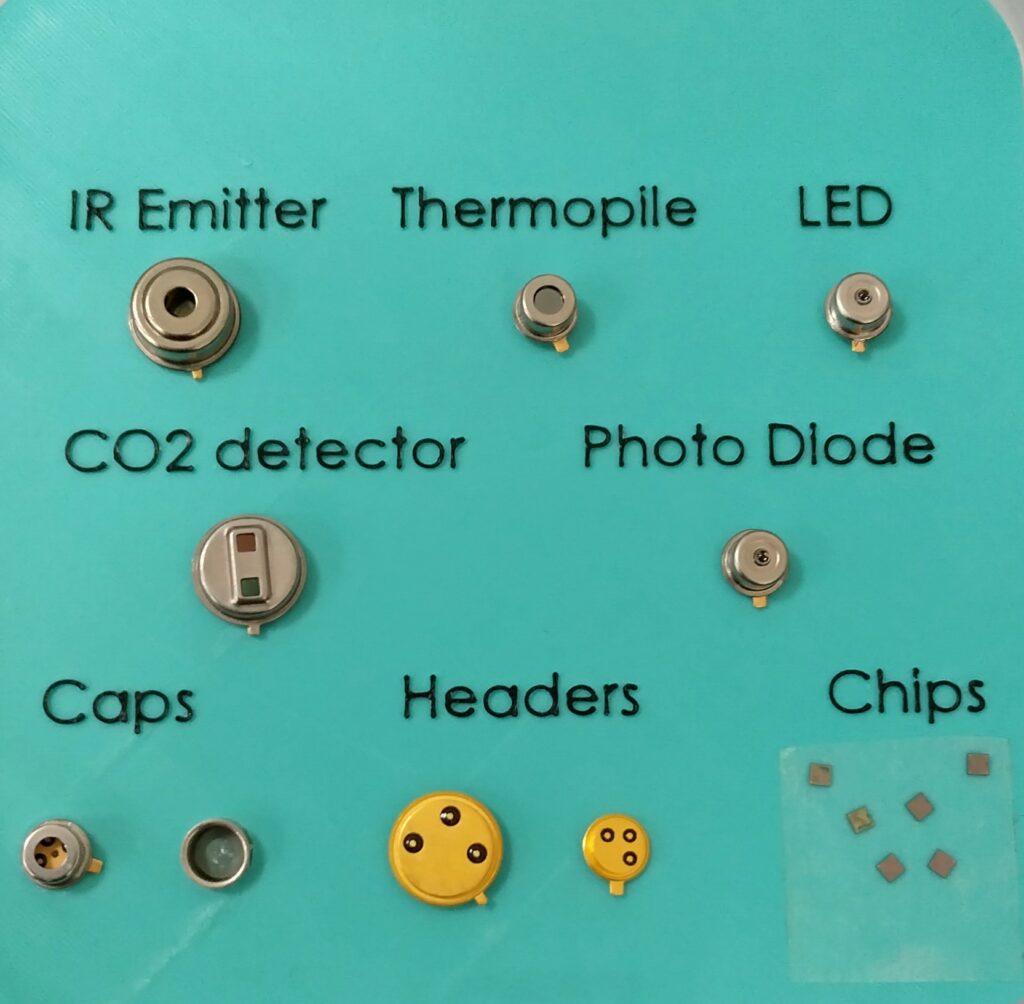

Precision Sensors Design provides high-reliability Hermetic Seal TO-CAN Packaging services, specializing in TO-46 and TO-5 metal can packages for sensors and semiconductor devices. Our OEM packaging service is designed to protect sensitive dies and wire bonds from environmental stress while ensuring long-term stability, accuracy, and performance.

We support both air-filled and nitrogen-filled capping, allowing customers to select the most appropriate internal atmosphere based on device sensitivity, performance requirements, and operating environment. This flexibility makes our TO-CAN solutions suitable for infrared sensors, gas sensors, MEMS devices, and other precision components.

Critical Importance of Capping After Wire Bonding

Capping is one of the most critical steps following wire bonding, as it permanently seals the device and directly impacts long-term reliability. Once wire bonding is completed, the exposed die and fine bonding wires are highly vulnerable to moisture, oxidation, mechanical damage, and contamination. Proper hermetic capping ensures these risks are fully mitigated.

Our capping process is carefully controlled to maintain bond integrity and internal cleanliness. Special attention is paid to temperature profiles, sealing pressure, and alignment to avoid stress on wire bonds or damage to the die. This ensures consistent electrical performance and prevents bond lift, corrosion, or signal drift over time.

Air-Filled and Nitrogen-Filled Hermetic Capping

- Air-Filled Capping

Air-filled TO-CAN packaging is suitable for applications where standard atmospheric conditions are acceptable. It provides robust mechanical protection and environmental isolation while maintaining cost efficiency for high-volume production. - Nitrogen-Filled Capping

Nitrogen-filled capping is recommended for high-precision and long-lifetime devices. By replacing oxygen and moisture with dry nitrogen, oxidation of bonding wires and sensitive die surfaces is minimized. This significantly improves signal stability, lifespan, and reliability, especially in infrared, optical, and gas-sensing applications.

Both options are performed in controlled environments to ensure low residual moisture and consistent internal conditions.

Key Quality Controls in the Capping Process

To guarantee high-quality hermetic packaging, we emphasize the following critical factors:

- Atmosphere Control: Precise control of internal gas composition and moisture levels

- Hermeticity Assurance: Secure sealing to prevent gas leakage and external contamination

- Thermal Management: Optimized sealing temperatures to protect wire bonds and die materials

- Mechanical Stability: Accurate cap alignment to avoid stress on internal structures

- Cleanliness: Particle-controlled environment to prevent contamination before sealing

These controls ensure each packaged device meets strict performance and reliability requirements.

Complete OEM Packaging Capability

Our TO-CAN OEM service includes:

- Die attach and wire bonding

- Air-filled or nitrogen-filled hermetic capping

- TO-46 / TO-5 metal can sealing

- Electrical testing and visual inspection

- Custom packaging solutions based on customer specifications

With years of experience in sensor and semiconductor packaging, Precision Sensors Design delivers consistent, high-quality hermetic TO-CAN solutions that meet the demanding needs of industrial, medical, and scientific applications.