At Precision Sensors Design (PSD), we provide end-to-end sensing solutions that span the entire product development lifecycle — from patent acquisition and advanced sensor design to manufacturing, packaging, testing, and final product delivery. Our comprehensive services are built to support customers at every stage, ensuring precision, reliability, and seamless execution.

Leveraging cutting-edge MEMS (Micro-Electro-Mechanical Systems) technology, we utilize a wide range of physical principles to develop innovative sensing components. Our deep expertise in sensor design and system integration enables us to deliver tailored, application-specific solutions that precisely meet each customer’s technical and commercial requirements.

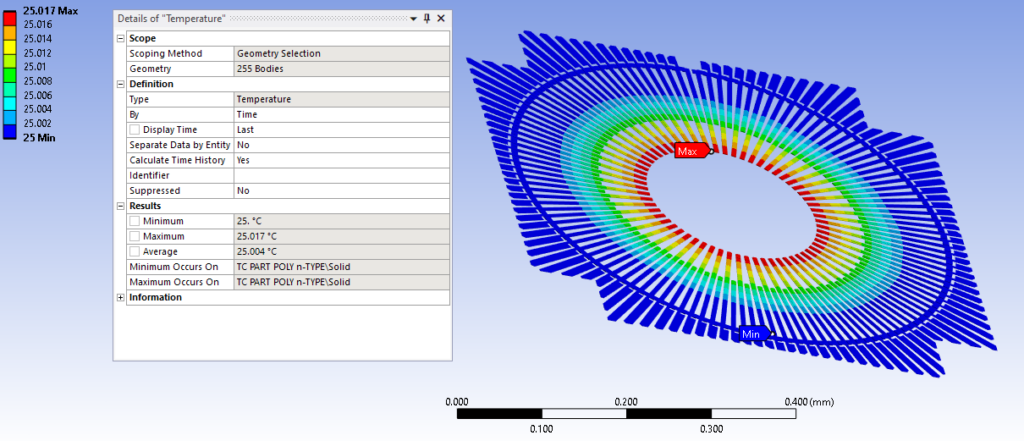

Sensor Design & Simulation

Our engineering team utilizes advanced design tools and simulation technologies to develop optimized sensor solutions that meet strict functional and performance requirements. Through thermal, electrical, and mechanical simulations, we evaluate sensor behavior early in the development cycle, reducing risk and accelerating time to market.

Precision Sensors Design Product Line-up

Key Capabilities:

- Custom sensor architecture design

- Performance modeling and optimization

- Noise reduction and sensitivity analysis

- Application-specific customization

Prototype Development

We support rapid prototype development to validate designs before mass production. Our prototyping process enables functional testing, design refinement, and early performance verification, ensuring a smooth transition into manufacturing.

Benefits:

- Faster design validation

- Reduced development cost

- Early performance feedback

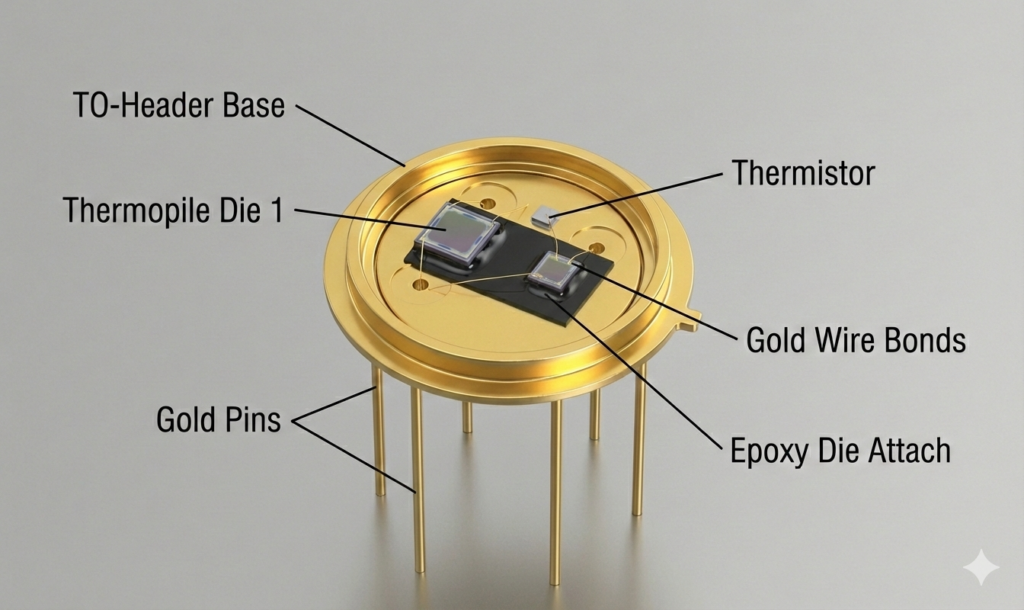

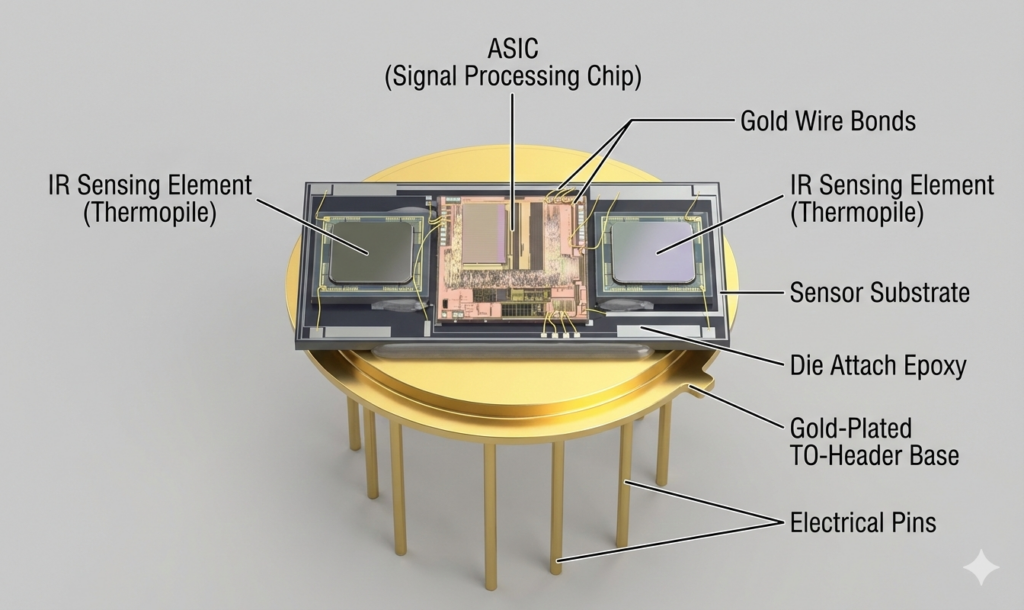

Die Bonding & Wire Bonding

Precision die bonding and wire bonding are critical to sensor performance and reliability. We use advanced bonding equipment to ensure accurate die placement, strong mechanical attachment, and reliable electrical connections.

Process Highlights:

- Micron-level die placement accuracy

- Optimized wire loop profiles

- High bond strength and stability

- Compatibility with various package types

Hermetic TO-CAN Packaging (TO-46 / TO-5)

We provide high-reliability hermetic TO-CAN packaging services to protect sensitive sensor components. Our packaging solutions offer excellent resistance to moisture, contamination, and mechanical stress.

Packaging Options:

- Air-filled hermetic sealing

- Nitrogen-filled hermetic sealing

- Custom cap configurations

Packaging & Testing

After packaging, every sensor undergoes systematic testing and inspection to ensure performance consistency and long-term reliability. Our testing procedures verify electrical characteristics, signal stability, and mechanical integrity.

Testing Includes:

- Electrical and functional testing

- Visual and mechanical inspection

- Performance verification under controlled conditions

Working Module Integration

Our working modules are designed for seamless system integration, combining sensors with optimized signal conditioning and interfaces. These modules reduce customer development time and simplify system-level design.

Applications:

- Embedded systems

- Industrial control

- Smart devices and IoT platforms

OEM & Custom Manufacturing Services

PSD offers flexible OEM manufacturing services tailored to customer requirements. From low-volume pilot runs to high-volume production, we ensure consistent quality and scalable output.

OEM Support Includes:

- Custom product configuration

- Volume production support

- Quality and reliability assurance

Technical Support & Consultation

Our experienced engineering team provides technical consultation and application support throughout the product lifecycle. We work closely with customers to ensure optimal sensor selection, integration, and performance.